The genuine ECU (DME) is constantly checking the work of the wheels.

How about these warning lamps?

ABS – antilock braking system

ESP – electronic stabilization program

DSC – dynamic stabilization control

DTC – dynamic traction control

They are the abbreviations of the brake’s and traction’s control systems. In reality they carry out many delicate controls.

These days’ cars are being controlled in a very complicated way. For this reason it is not easy to test drive them on a roller.

Let us introduce you DIM-TECH.

The head office of the DIM group is around 100km away from Milan, Italy. DIM-SPORT is a leading European company dealing with data tuning systems. For a high level data tuning a chassis dynamo tester with high efficiency is necessary. DIM-SPORT became independent from the chassis dynamo maker it used to work with and started developing its own system (Dyno-Race). This company inside the DIM group is called DIM-TECH.

Even if the usual rollers are for 4WD, the front and back rollers are independent. For this reason, if the car is an FF car only the front wheel rotates, if the car is an FR car only the rear wheel rotates.

However, under real driving conditions this kind of movement doesn’t happen and that’s why the ECU (DME) interpretes it as an abnormality.

When the ECU recognizes the abnormality the injector in the meter panel starts flashing and lets the driver know about the situation. Not only the alarm lamp flashes but also the ECU enters into full saving mode and the output lessens. If this happens it becomes impossible to make measurements on the roller. In some cases the ABS causes malfunction and even while speeding an abrupt braking might occur. This is very dangerous.

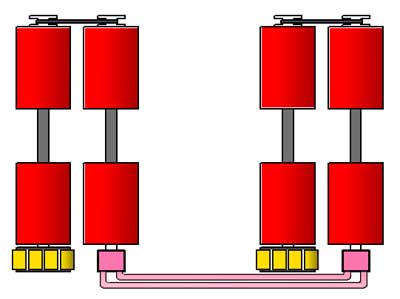

Now, let us explain about DIM-TECH’s tester’s (Dyno-Race) biggest characteristic, the ESS mechanism.

ESS is the abbreviation of Equalizing Speed System.

The front and rear rollers are connected hydraulically. If one roller starts rolling the roller on the same side becomes synchronized.

The couple rollers of the front wheel side and the rear wheel side are connected by a belt. For this reason if one of the rollers rotates all the other rollers start rotating.

In the case of 4WD cars isn’t it a problem if the front roller and the rear roller are not connected?

The fact is that for example in the case of a 4WD BMW when we control the front and rear torque distribution by ECU but the front and rear rollers are not connected, there will be difference in rotation between the tires.

This kind of difference doesn’t occur under usual driving conditions, only in the case of slipping. For this reason the ECU recognizes it as abnormality.

In other words, in all of the FF cars, FR cars, RR cars and 4WD cars the ESS mechanism is effective.

A loading equipment (electric brake) is being set up at the front and rear rollers.

It is possible to apply load and carry out a very precise road simulation.

Furthermore, it is possible to carry out tests with fixed torque, fixed rpm etc. and with this ECU tuning can be handled.

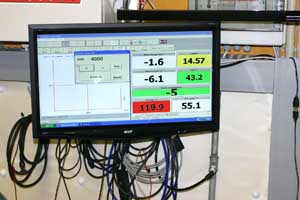

There are 8 measured items.

One is road simulation.

BMW-MINI (RS6S), FF car

The front and rear tires rotate using DYNO-RACE with ESS mechanism.

If we input the car weight, tire size, frontal projected area, Cx rate, speed, road grade etc. it is possible to reproduce the conditions and the program applies load.

By controlling the

・torque and

・running distance

the car can be checked comprehensively using the sensors.

For example not easily recognizable strange noises, vibrations, bad automatic transmission, overheating, bad engine output etc. can be reproduced.

The ESS mechanism and electric brake are useful even for general power check but the additional measurement program is also very good.

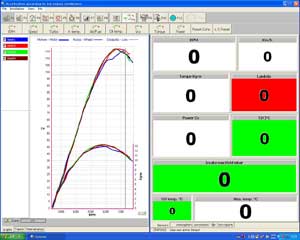

First, we input the initial rpm and the final rpm of the power measurement.

Then we choose the measuring time between these two.

For example if we enter:

START/2000rpm~FINISH/7000rpm・・・18seconds

the brake will be programmed automatically.

If we set a longer time it is possible to get better sampling.

Even if we turn off the accelerator halfway the measured data will be sampled.

Even if we change to standard speed the same measurement is possible.

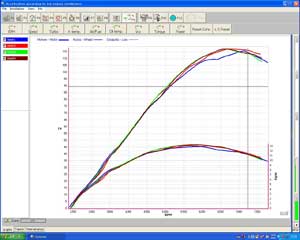

The data can be compared on a graph. It is very useful when comparing with other cars or analyzing the effect of tuning items.

All the sensor probes from the control box are connected and collective data sampling becomes possible.

Engine rpm・manifold pressure・intake air temperature・oil temperature・Lambda (A/F) etc.

All these data can be compared and analyzed by the graph.

Usually, the engine rpm is being picked up from electric parts (plug code・igniter・ignition signal). However, it is not easy to get the ignition signal from the electric parts.

Also, there are some cars that’s engine won’t start with an open hood.

In the case of Dyno-Race we decide the gear ratio and while rotating the roller, it is possible to synchronize it with the tachometer and the dyno PC.

By using DIM-TECH’s special fan unit and inverter it is possible to turn the fan ON or OFF. Furthermore, if we set the automatic operation mode depending on the vehicle speed the cooling fan’s strength becomes automatic.

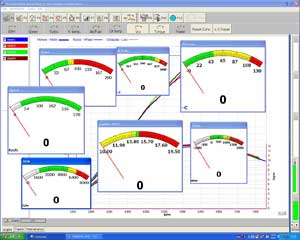

The function key can be found on the upper part of the main screen.

The measuring graph is on the left side and the measured data are displayed on the right.

The sampling numeric value can be displayed by the analog meter.

A maximum of 8 samplings can be displayed.

The tester can be set up in ground or on the ground (a slope is necessary).

[home]