01R/28R Type-C Miata MX-5 NA6/NA8

We have some good news for you.

Maruha Motors launched a lightweight flywheel, the Type-C.

Our new line is billeted using Chrome-molybdenum steel.

To develop the new product we kept in mind its performance improvement

and the greatly satisfying specs.

Let us introduce you the five special features of Type-C.

1. High-tech machine billeting Chrome-molybdenum steel

As you know, our new Type-C is made from Chrome-molybdenum steel.

This substance is from chrome-molybdenum containing carbon steels.

Due to its features, like the tensile strength it is our ideal material to

create Maruha's lightweight flywheel, enhancing its rigidity.

▲01R Type-C for B6 engine (5.7kg)

▲01R Type-C for B6 engine (5.7kg) ▲28R Type-C for BP engine (6.2kg)

▲28R Type-C for BP engine (6.2kg)フライホイール 01R Type-C 単品 STD 5.7kg(2020年6月〜)

code:mar04121601 For NA6 NB6

¥40,260(¥36,600)

フライホイール 28R Type-C 単品 STD 6.3kg(2020年6月〜)

code:mar04121602 For NA8 NB8

¥46,530(¥42,300)

▲New flywheel package

▲New flywheel package

▲Contains cushioning material.

▲Contains cushioning material.

Because of its low cost, we have remade the genuine flywheel for our

former models.

The reason why we remade it, was that so many users needed slightly

light-weight flywheels.

It was the shortcut to meeting our customer's needs.

To make flywheels of great precision, Maruha operated the machining centers

for the wheels only.

The Type-C is produced, maximizing the know-how of our existing goods.

The high-quality and rational process allowed the production of the new product.

By shaving the flywheels with a single specialized machine, it can perform

from the peripheral milling to making the pinholes and the female threads.

As a result, there is no spacing error found in a huge number of flywheels.

Moreover, we do not need to adjust different kinds of machines for each process.

In addition, you won't find any unnecessary holes on the Type-C to make the product light.

Multi-hole lightweight flywheels are not ideal, as these holes will cause

serious damage to them like distortions and unbalancing.

Maruha's motto is to avoid opening the holes as much as possible, even if you

need lighter flywheels.

Throughout our elaborate work Type-C became mightier

and better balanced.

2. Offering a smooth and steady drive

The average lightweight flywheels that have been sold without any questions

on the tuning market are approximately 4kg heavy. It is half of the weight of the genuine

MIATA ones.

If you want a hot wild drive like during races, these flywheels have some merits

including the improvement of the pickup and that of the engine brakes.

But if you do not, is there any meaning of lightweight flywheels?

Heavier genuine ones tend not to be picked up.

When you drop the hammer roughly, they are unable to operate quickly.

They make a steady drive.

Basically, you can drive in the city maintaining an even pace, as opposed to

lighter flywheels, accelerating and slowing down quickly, that produces an

uncomfortable ride.

What is the secret of keeping your car more comfortable? The

answer is Type-C.

It is heavier than a great number of lightweight flywheels on the market -

01R(for B6) 5.7kg / 28R(for BP) 6.2kg.

Our products will give you a smooth and stable drive.

When you change the clutch on your car, in addition, Maruha recommends changing

the flywheels.

Well, even if you do not want a wild run, Maruha's Type-C has two important characteristics.

At a reasonable price your drive becomes more enjoyable.

Once you try our Type-C you won't be able to live without it.

3. Proper heat treatment

It is easy to see flywheels made from Chrome-molybdenum steel on the tuning

market. Actually, you can find many lightweight Chrome-molybdenum flywheels on

the net, though some of them seem to be fakes. Certainly, it is important to use

the finest material. But even with the finest ingredients, can anybody

cook wonderful dishes?

We can say the same about flywheel production. To

exploit the material's features, Maruha emphasizes one process.

It is the heat treatment process. The heat treatment improves the toughness and

the anti-galling effect of Type-C.

The flywheel makes the clutch disc clung firm

to the pressure plate. To complete the task, this process is never missed.

However, on the market, there are Chrome-molybdenum flywheels, slightly or not treated by heat. However, it is important to understand that improper heat treatment causes distortions.

We always manage to make long-life and easy-to-use products. So, the Type-C comes in mat gray color. It proves that this flywheel was treated well by heat.

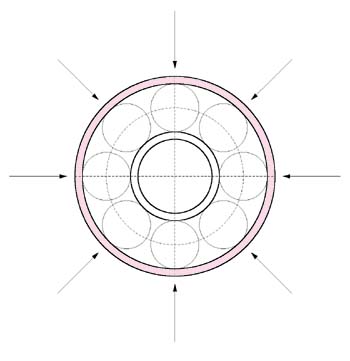

4. Non distorted pilot bearing with dropout prevention system

When you drive a car that has been driven for many years, it makes odd

sounds.

Do you have such an experience?

These sounds might be a sign of

deterioration of the pilot bearings.

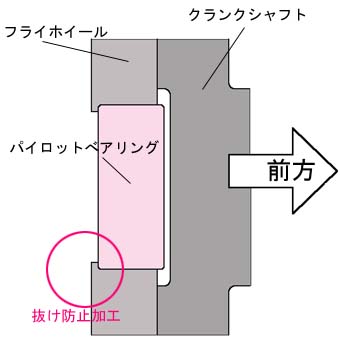

The pilot bearing guiding the main shaft of the transmission is pressed into the flywheel.

Small precision balls are inside of

the bearing.

By pressing into the flywheel, the bearing surface becomes

distorted and as the result of it, the balls are forced to be pressured from the

outside. And finally, the bearing moves roughly, even though it rounds smoothly

before being pressed.

Due to their vibrations, hard drives like races make the bearings drop

from the flywheels.

After races, at the moment of removing the transmissions and

the clutch covers, the bearings drop off. For streetcar users,

conversely, it is rare to remove the transmissions from their cars and we need

to design our products to maintain their longer lives.

Maruha's Type-C has good news for pro shops that have accepted that bearings are never prevented from falling out of place. A stopper, on the center of the Type-C, prevents the bearing from coming out.

The bearing is pressed from the tail side of the crankshaft. By attaching the flywheel, the tail of the shaft prevents the bearing from dropping out. Our refinement can help load the pilot bearing with less power and also avoids its distortion.

Pressing the bearing causes its surface distortion and its balls are

pressured.

This case lets the bearing move roughly. As a result of it, the

bearing has a short-life span.

5. Improving knock pins

Three knock pins that position the clutch cover, are pressed into the flywheel.

As six bolts fix the cover to the flywheel, indeed, it seems that the pins are

unnecessary.

Why are they installed on flywheels?

The clutch cover has some holes wide enough to penetrate the bolts.

If they have no allowance, it is hard for the bolts to go through and their threads

become stripped.

Therefore, the holes are slightly larger.

Actually, the knock pins are used to center the clutch.

However, when we checked several genuine MIATA flywheels by our 3D

measuring tester we found some differences between the positions of the pins, though there is no problem with safety.

They also lead to difficulty with attaching the genuine clutch cover.

This rigorous examination can help us design the Type-C.

We equalize the positions of the knock pins and the pin diameter is changed to

the ideal size.

Some flywheels made by other manufacturers have pin diameters in much smaller

sizes but

there is a problem with centering the clutch.

The Type-C, in contrast, will help you fix the clutch cover smoothly and

center the clutch precisely.

NEW OIL!!

ESTER27 Full Synthetic♪

NEW TOPICS

CARBON TIMING COVER